What are you looking for?

PCB Connectors

PCB Connector

Rugged, Modular & High-Performance Interconnect Solutions

At Nicomatic, we design and manufacture high-reliability PCB connectors tailored for demanding environments and critical applications. Our connectors are engineered for performance, compactness, and versatility, making them ideal for use in aerospace, defence, space, and military sectors.

Why Choose Nicomatic PCB Connectors?

- Modular Design: With our signature modular platform, you can configure your connector exactly to your needs — choose the number of contacts, fixing, layout, mixed signal options (signal, power, coax, or fiber optics)and even at what angle will the connector connect to the board or cables?

- Robust Construction: Nicomatic connectors are designed to withstand shock, vibration, high temperatures, and harsh environmental conditions. Many series meet or exceed MIL-DTL-55302F, MIL-DTL-83513 (Micro-D), and EN4165 standards.

- Compact Footprint: Our PCB connectors offer high-density solutions for space-constrained applications without sacrificing performance or durability.

- Fast Delivery: Custom configurations delivered in 4 to 6 weeks, thanks to our agile production model.

Key Product Lines

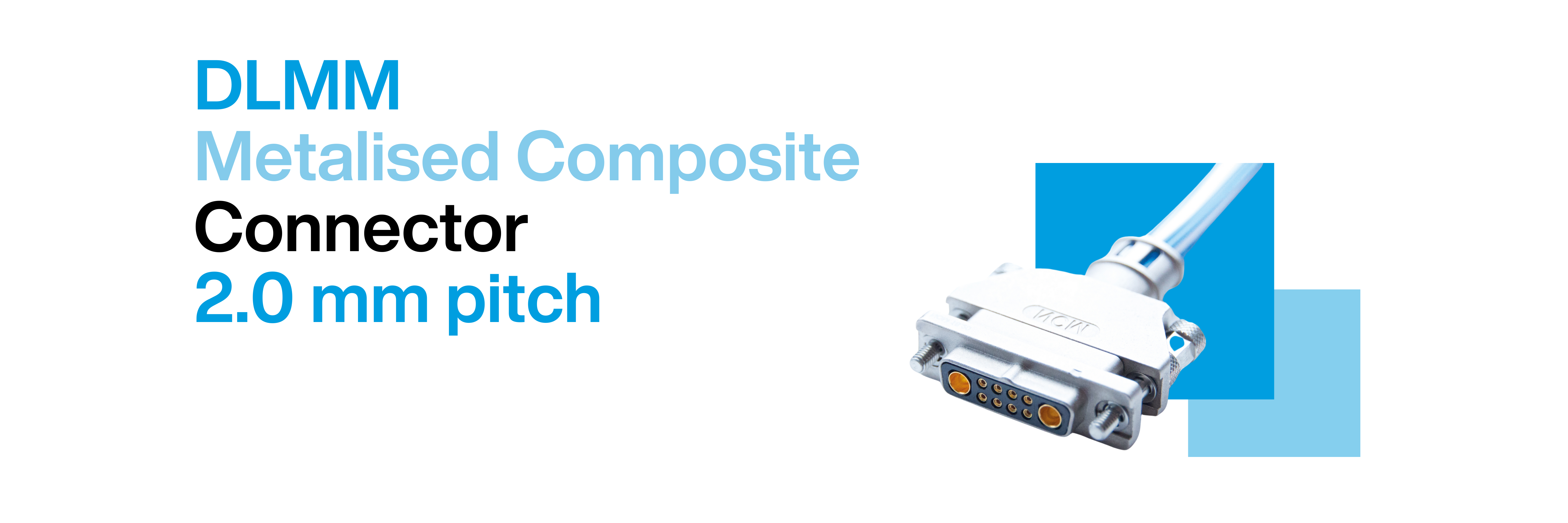

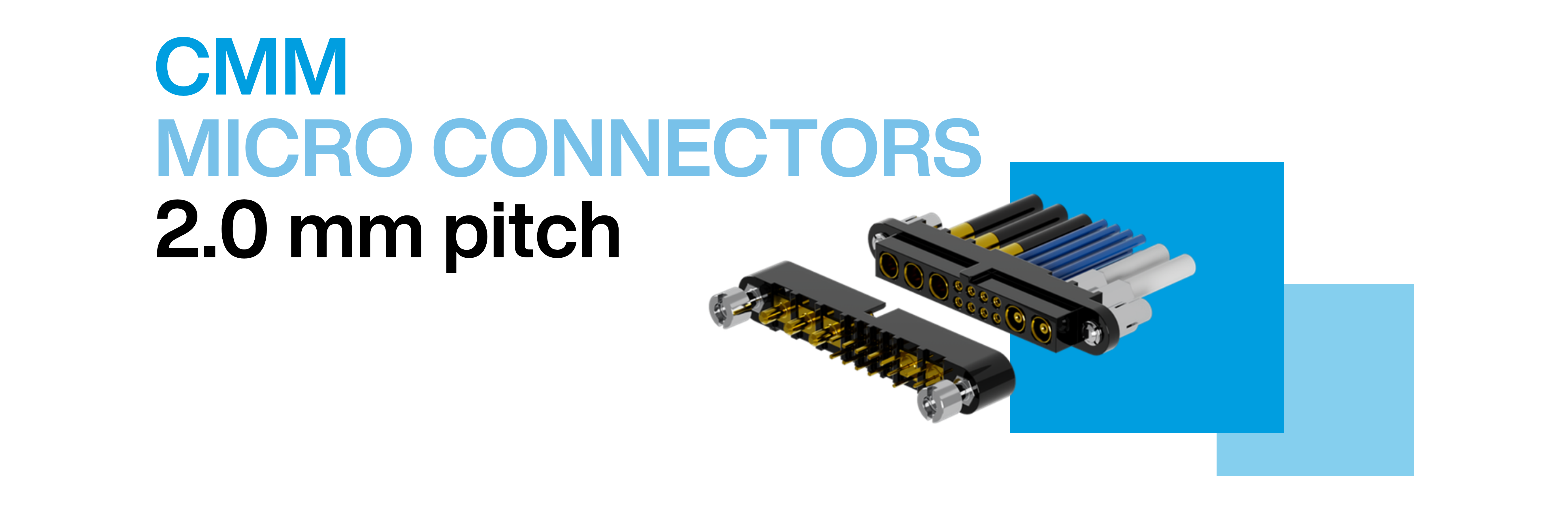

CMM Series – 2.00 mm Pitch Modular Connectors

- MIL-DTL-55302F compliant

- Mixed layout: signal, power, coax

- Surface-mount or through-hole PCB versions

- Up to 120 signal contacts

- EMI protection options available

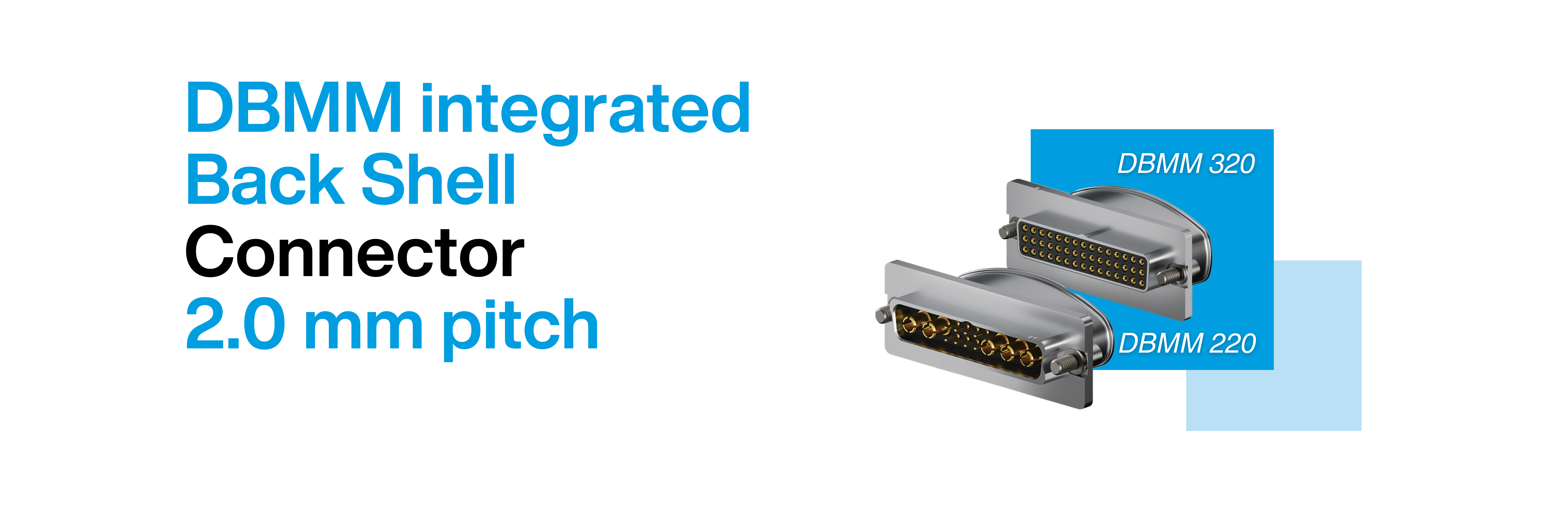

DMM Series- 2.00 mm Pitch Metal Connector

- High modularity: contacts Signal ( LF), Power (HP), Coax (HF) and optic fiber, up to 10M arrangements

- Board to board, board to wire, wire to wire, panel mount (1 to 4 rows of contacts)

- Miniaturisation: low profile

- Ruggedized with aluminium alloy 6061

- Easy maintenance thanks to dismountable contacts And easy assembly, thanks to the patch that comes pre-assembled on the connectors

EMM Micro connectors - 1.27mm pitch

- Designed to meet the performance requirements of MIL 83513

- Suited to both board-to-board and board-to-wire (24-30 gauge) configurations.

- Available from 04 to 60 signal contacts.

- Moulding: High performance glass fiber composite (LCP)

- Fixing hardware: passivated stainless steel 300 series

AMM Series – Ultra-Low Profile 1.00mm Pitch

- Designed for weight and space-critical applications

- Offers 5 standard layouts including 06, 10, 20, 34, and 50 contacts.

- Straight through PCB, male and female SMT on PCB, female on cables.

- Ideal for avionics, drones, and miniaturized electronics

Applications

- Avionics and military equipment

- Space payloads and satellite subsystems

- Industrial automation and robotics

- High-speed data transmission modules

Your Reliable Partner for Custom PCB Connectors

At Nicomatic, every connector is an opportunity to push the limits of performance and innovation. Whether you're designing for extreme environments or integrating high-density electronics into compact spaces, our team is here to help you find or build the right PCB interconnect solution.

Need a custom connector or technical support?

Contact us today — our experts are ready to support your project from concept to production.

BackShell assembly instructions on DMM connector

Connectors and wiring solutions

Questions / Answers

What types of power connectors does Nicomatic offer?

How to choose the Power connector for my application?

What standards do the Nicomatic power connectors meet?

What is the average shelf life of a Nicomatic power connector?

Can you customize power connectors for certain needs?

What are the normal delivery times for your power connectors?

How can I get a quote for a large quantity of power connectors?

What payment methods are accepted for purchasing power connectors?

What is a single contact (signal)?

What is HF contact?

What is the HP touch?

What is EMI?

What is RFI?

What is EMI/RFI protection?

What is COAX contact?

How do you choose a connector according to frequency (HZ) and impedance (Impedance-Ω)?

When to choose a plastic connector and when to choose a metal connector?

What is the advantage of SMT contacts (Surface Mount Technology) compared to intrusive contacts on the PCB?

Golden advice for designing connectors on a PCB board

.png?size=100%)

.png?size=100%)