"It’ll be too expensive.” “We don’t have time.” “Relying on one supplier is risky.”

👉 Sound familiar? These are common statements in the middle of a project, when deadlines are tight, budgets are limited, and space or environmental constraints are critical. That’s when the big question arises: should we really consider a custom connector?

In demanding development contexts, there are plenty of reasons why a custom solution makes perfect sense:

- Limited PCB space,

- The need to replace an obsolete component in an existing system,

- Specific design or environmental constraints that standard solutions can’t meet.

At Nicomatic, we work with engineers facing these challenges every day. And here’s what we’ve seen: these myths often prevent smart technical choices that could actually make your project easier.

Myth #1: “Custom is too expensive”

The unit price of a connector is just one part of the story. What truly matters is the total cost of your solution: from integration and assembly to logistics. And that’s where custom can actually be more cost-effective.

For example: a custom connector can replace multiple standard references.

The result? Simplified architecture, fewer wiring errors, freed-up PCB space, and easier maintenance.

It can also enable system miniaturization, reducing weight, a key benefit in aerospace and space applications.

Additional technical benefits:

- Better sealing and shielding,

- Improved signal integrity,

- Increased resistance to shock and vibration.

A custom connector is often more compact, more robust and ultimately, more efficient.

Myth #2: “It’s too slow and complex”

Custom might sound like a long and painful process but the reality is quite the opposite, with the right partner.

At Nicomatic, our custom process is fast and straightforward:

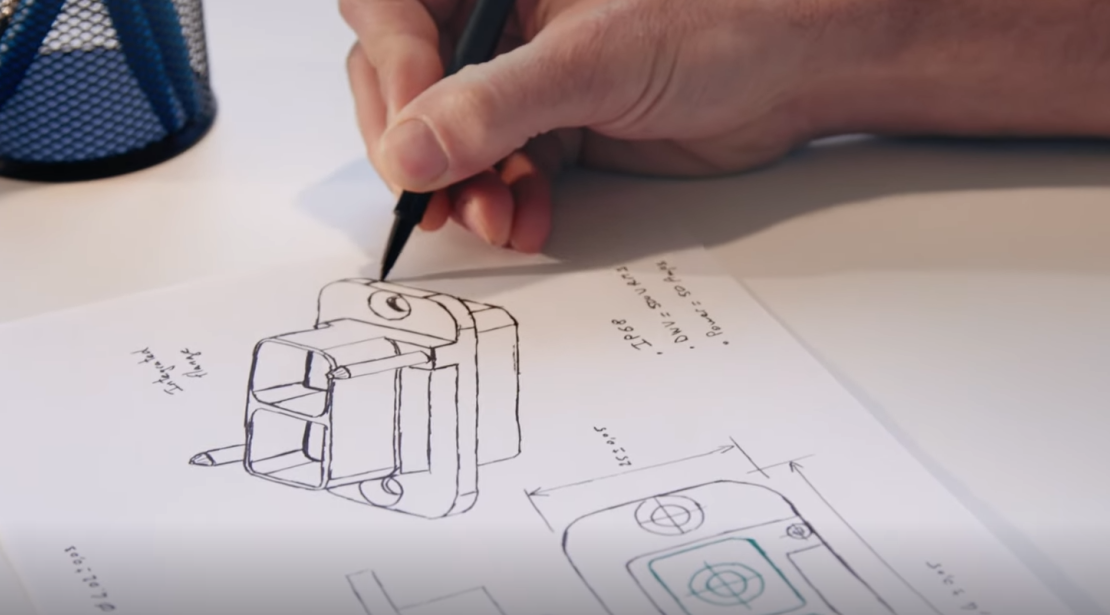

- You share your requirements, even a sketch or a few technical specs are enough.

- Our engineers reply within 72 hours with a feasibility study or recommendations, a first technical exchange to lay the groundwork for the project.

- Once feasibility is confirmed, we launch the custom design phase, based on your technical and environmental constraints.

- Once approved, we start prototype production. Lead times are similar to standard solutions on market: between 4 and 12 weeks.

Each year, we handle over 500 customization requests, with 90% receiving a first response within 5 days.

And remember: the earlier you involve us in your design cycle, the smoother the process. It helps you avoid costly last-minute changes and keeps your timeline on track.

Myth #3: “One supplier? Too risky.”

A fair concern: relying on a single source can seem risky. But it all depends on the partner you choose.

A reliable, committed supplier means:

- Simplified logistics,

- Consistent quality from end to end,

- Technology exclusivity that sets your design apart, a true competitive edge, with access to advanced technologies often not yet available on the market.

With Nicomatic, you get:

- A family-owned company with 50 years of expertise in aerospace, space, and defense,

- A global presence with 20+ entities and multiple production sites,

- Customization as a core specialty, with dedicated engineering teams and production lines,

- Proven experience in harsh environments,

- EN9100-certified in-house production, fully controlled from start to finish.

Still unsure? Our doors are open! You're welcome to audit us, visit our facilities, and see our processes in action.

Partnering with Nicomatic means choosing long-term reliability.

In Summary?

A custom connector isn’t a luxury. More often than not, it’s the smartest answer to your real needs, technically and economically.

At Nicomatic, our promise:

- MOQ: only 1 unit

- Lead times similar to standard solutions

- Engineer-to-engineer support throughout your project

Let’s Talk.

Tell us what you need, even just a few lines, and let’s explore how a custom solution can work for you.