In harsh environments, you know it well: every interconnection is a critical point.

Vibrations, extreme temperatures, space constraints, interferences… the slightest compromise on cabling or connectivity can impact overall performance and, in some cases, compromise the mission.

You often have to deal with:

- Weight and volume constraints limiting your choices.

- Guaranteed electrical continuity against electromagnetic disturbances.

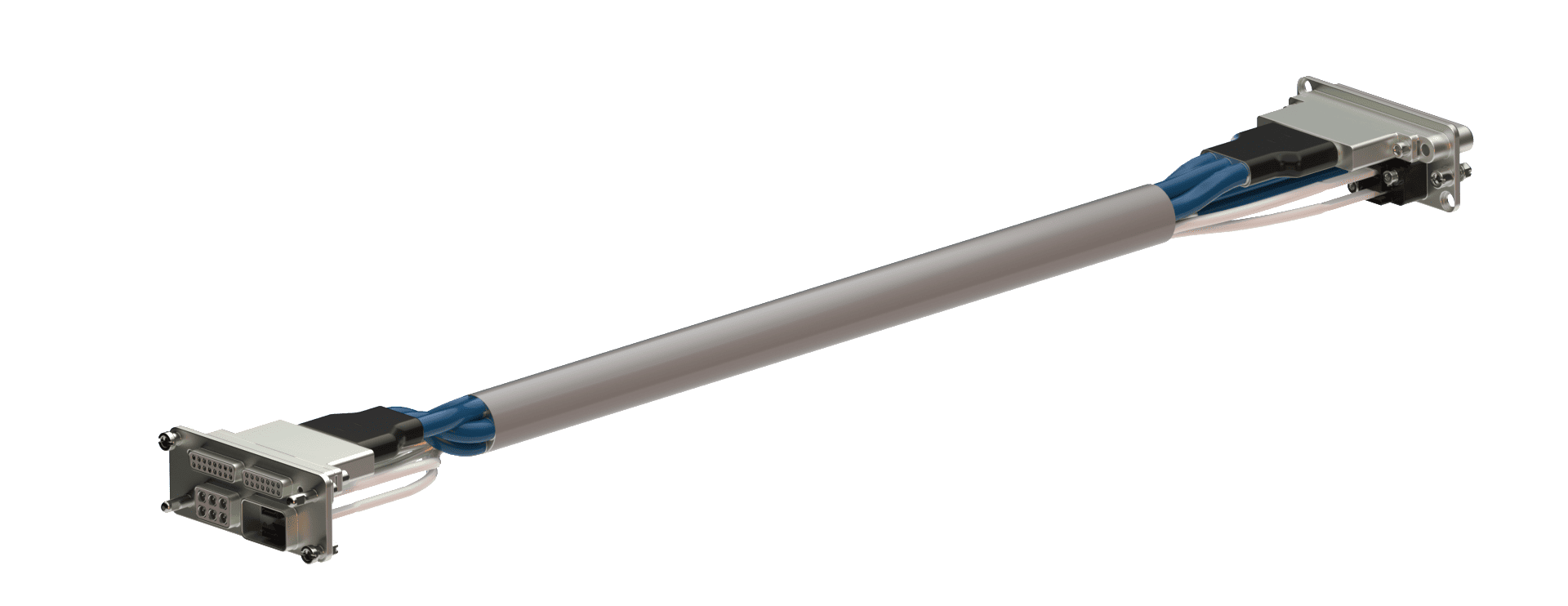

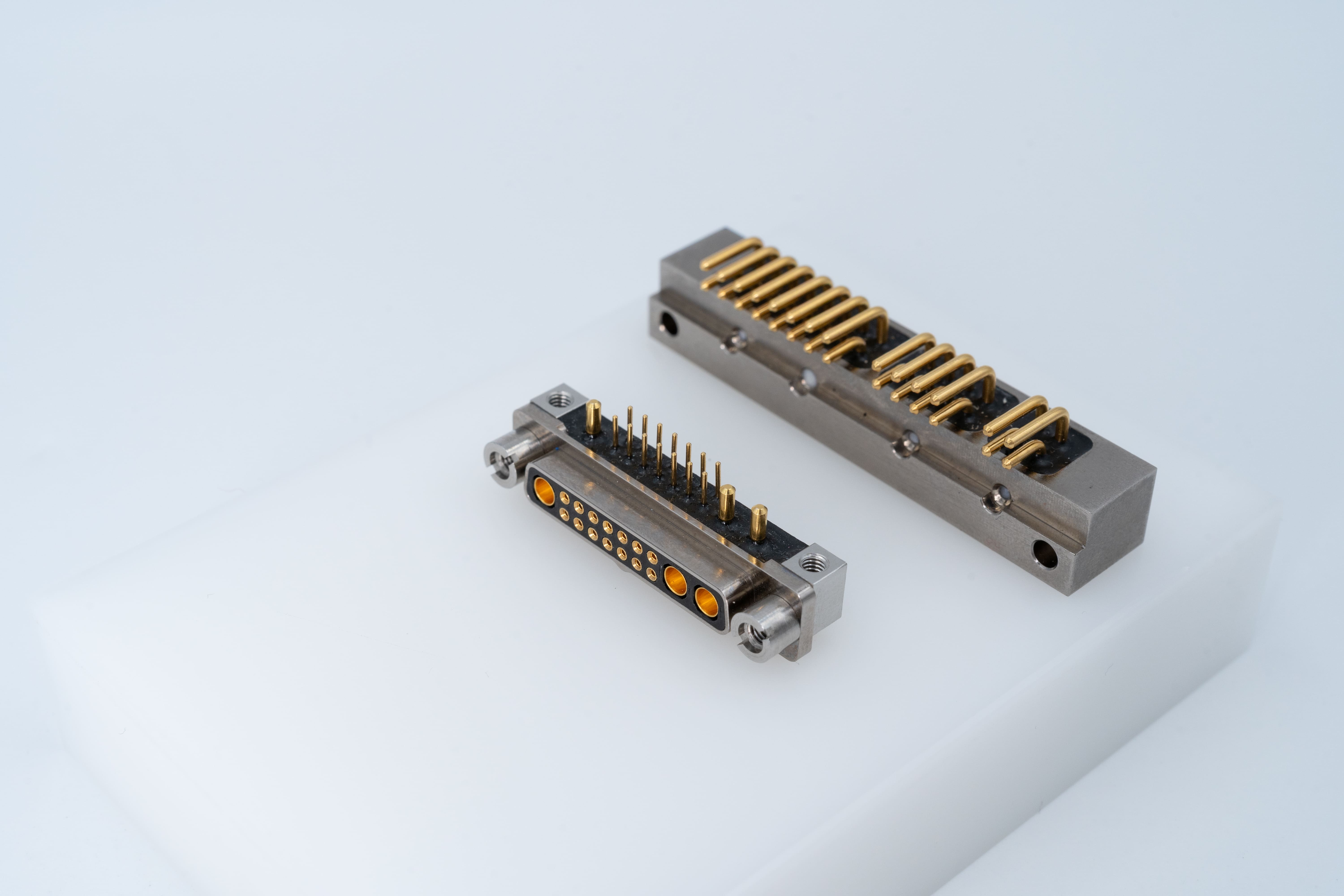

- Hybrid architectures combining power, signal, and high-frequency transmission.

- Tight deadlines, with the risk of requalifying the entire system if one element changes.

- Simplified maintenance, without weakening the installation.

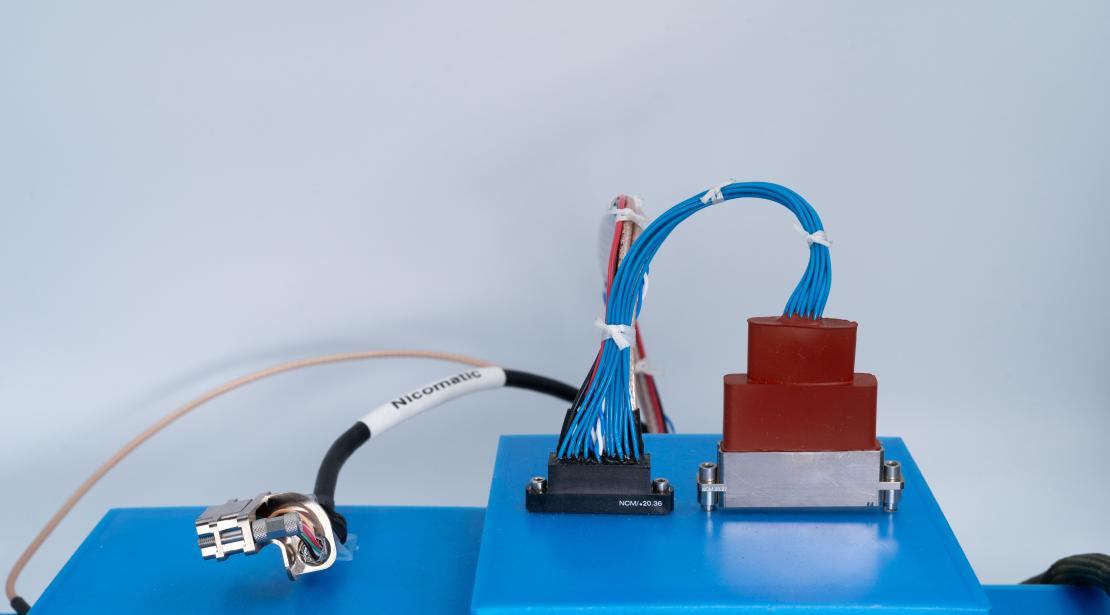

To meet these challenges, we have developed a complete approach, covering from cable to connector, to design reliable, robust solutions adapted to your environment.

Custom Cabling: Built-in Reliability from the Conception

We manage every step in the production of custom harnesses, tailored to your electrical, mechanical, and environmental requirements:

- Cable types: signal, power, coax, optical

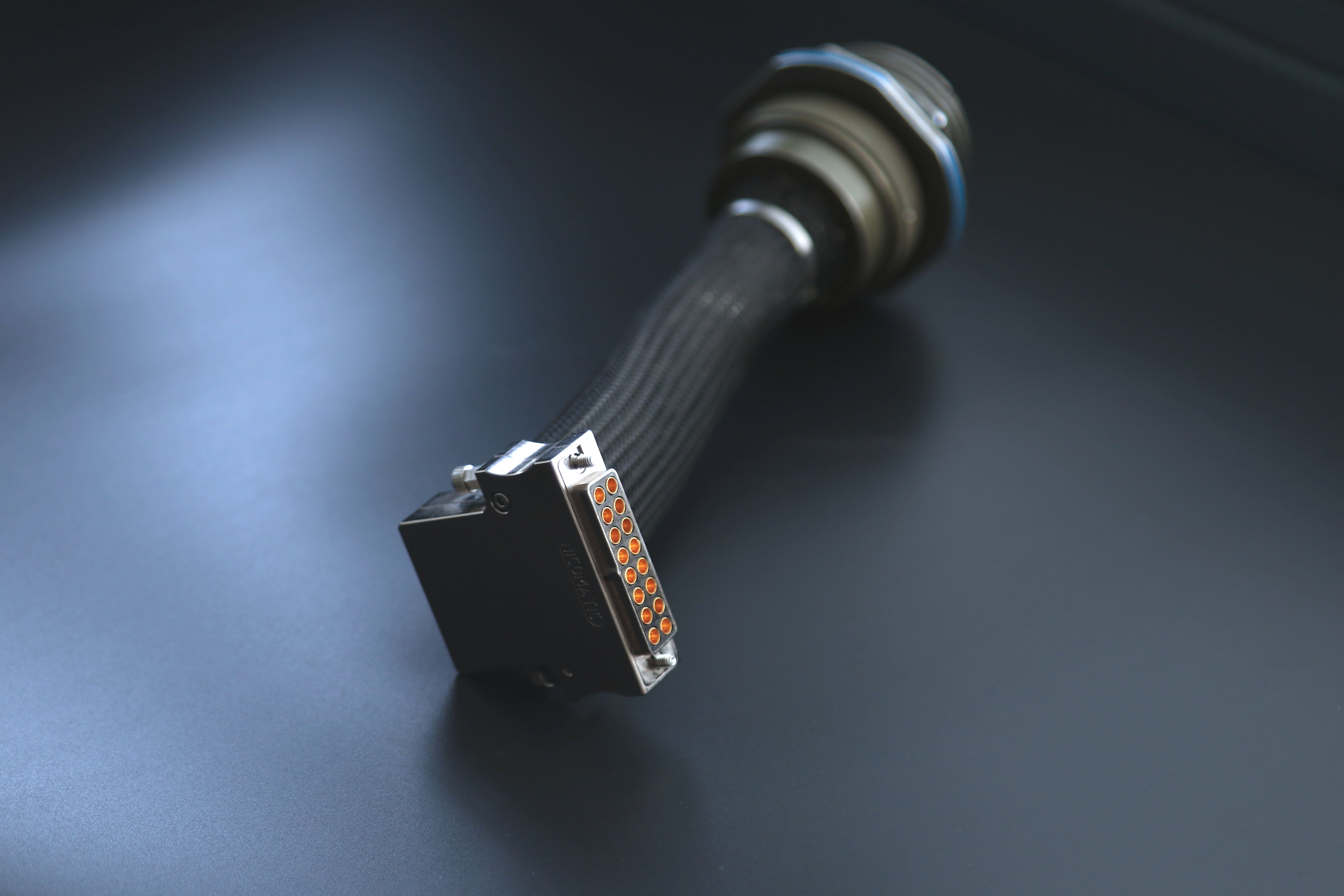

- Rugged cable assemblies built to withstand the harshest thermal, vibrational, or environmental constraints.

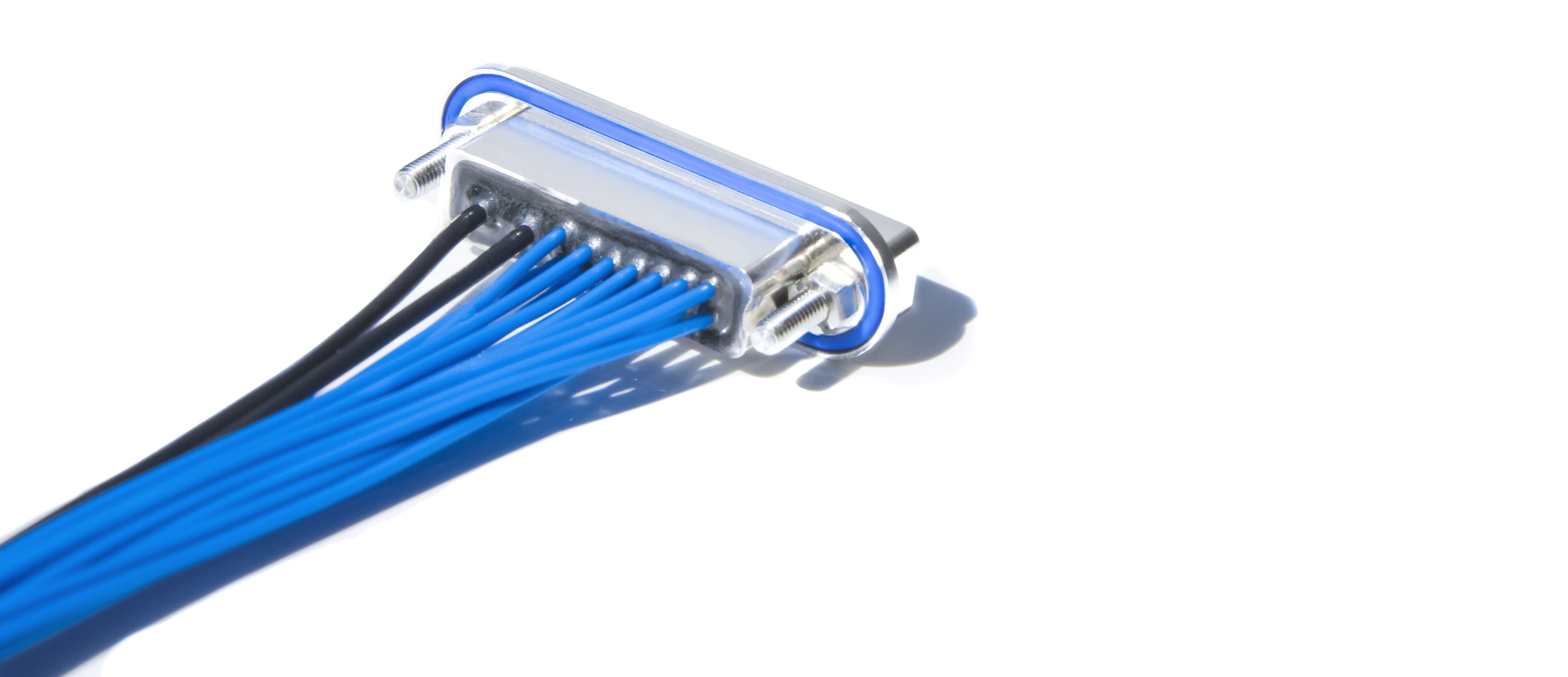

- High-precision assemblies: crimped wires, heat-shrink sleeves, shielding braids, mechanical protections

- High-pressure overmolding to withstand harsh environments

- Electrical testing on configurable benches to guarantee continuity and insulation

- On-site assembly for critical or confidential configurations

With our state-of-the-art machinery (laser wire stripper, modular tooling, test benches), you benefit from quality, repeatability, and responsiveness.

From Transmission to Connection Point

Even the most efficient harness won’t deliver its full potential if the connector interface isn’t optimized.

You see it every day: space management, hybrid signal handling, mechanical compatibility, shielding, maintenance access… this is often where reliability is determined.

That’s why we integrate cabling and connectivity within the same approach, ensuring technical consistency and end-to-end robustness.

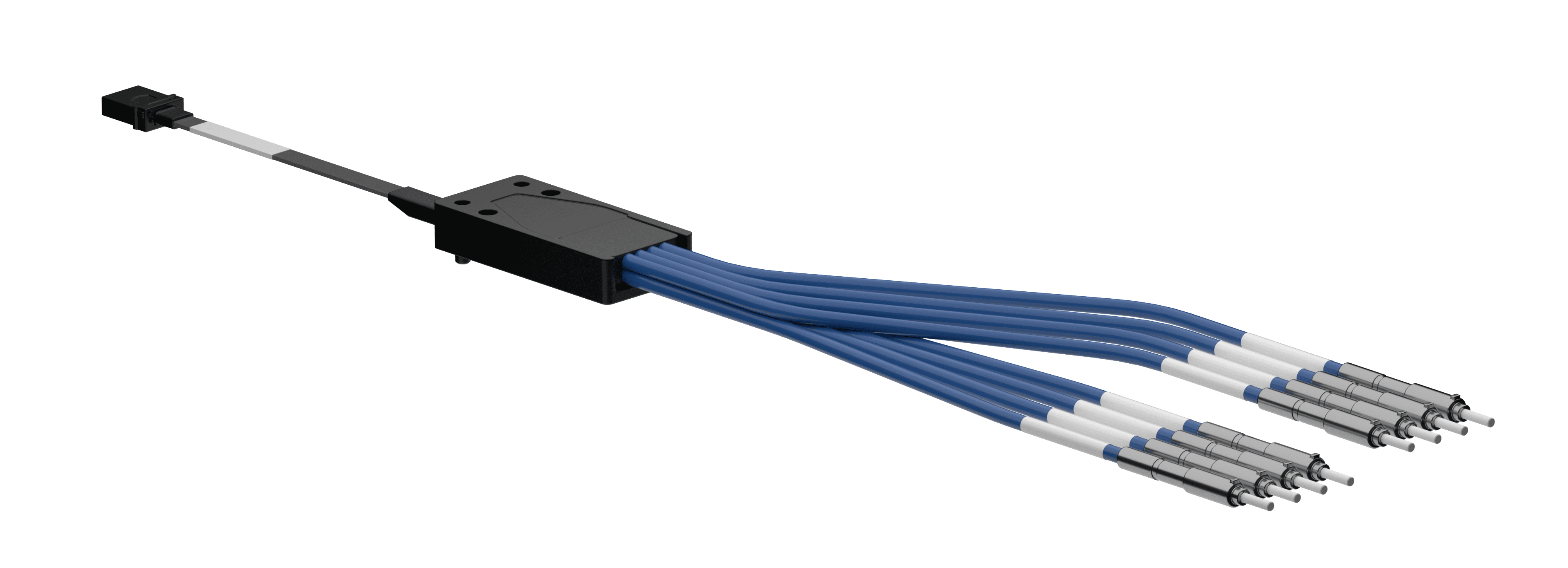

Custom Connectivity: Beyond Standard Modularity

At Nicomatic, we believe every application requires a unique solution. That’s why we provide build-to-spec options, from minor adjustments on existing models to fully customized designs without minimum order quantities and within relatively short lead times.

The most popular customer requests:

- High-speed connectors, preserving signal integrity in critical applications.

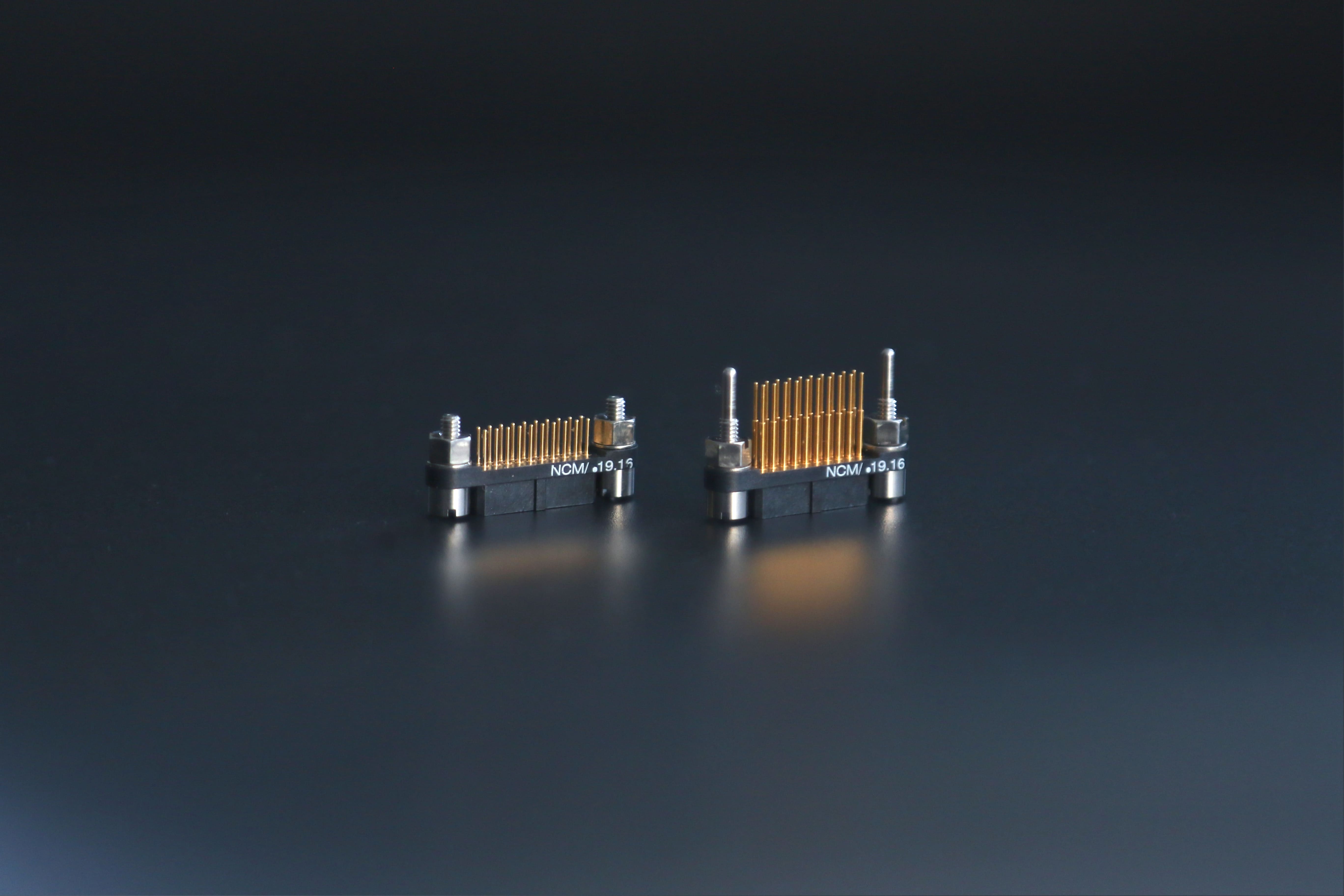

- PCB stacking connectors, providing precise board-to-board or mezzanine connections without compromising space.

- Sealed connectors, IP67/IP68-rated, ensuring reliability in humid or dusty environments.

- Backpotting, to protect your contacts against residues or conformal coating.

- Savers, protective elements designed to reduce connector wear in high-mating-cycle applications.

- EMI-shielded connectors, protecting your links against electromagnetic interference.

- A full range of custom accessories: backshells, dust/ESD protective caps, and interface gaskets for reliable sealing.

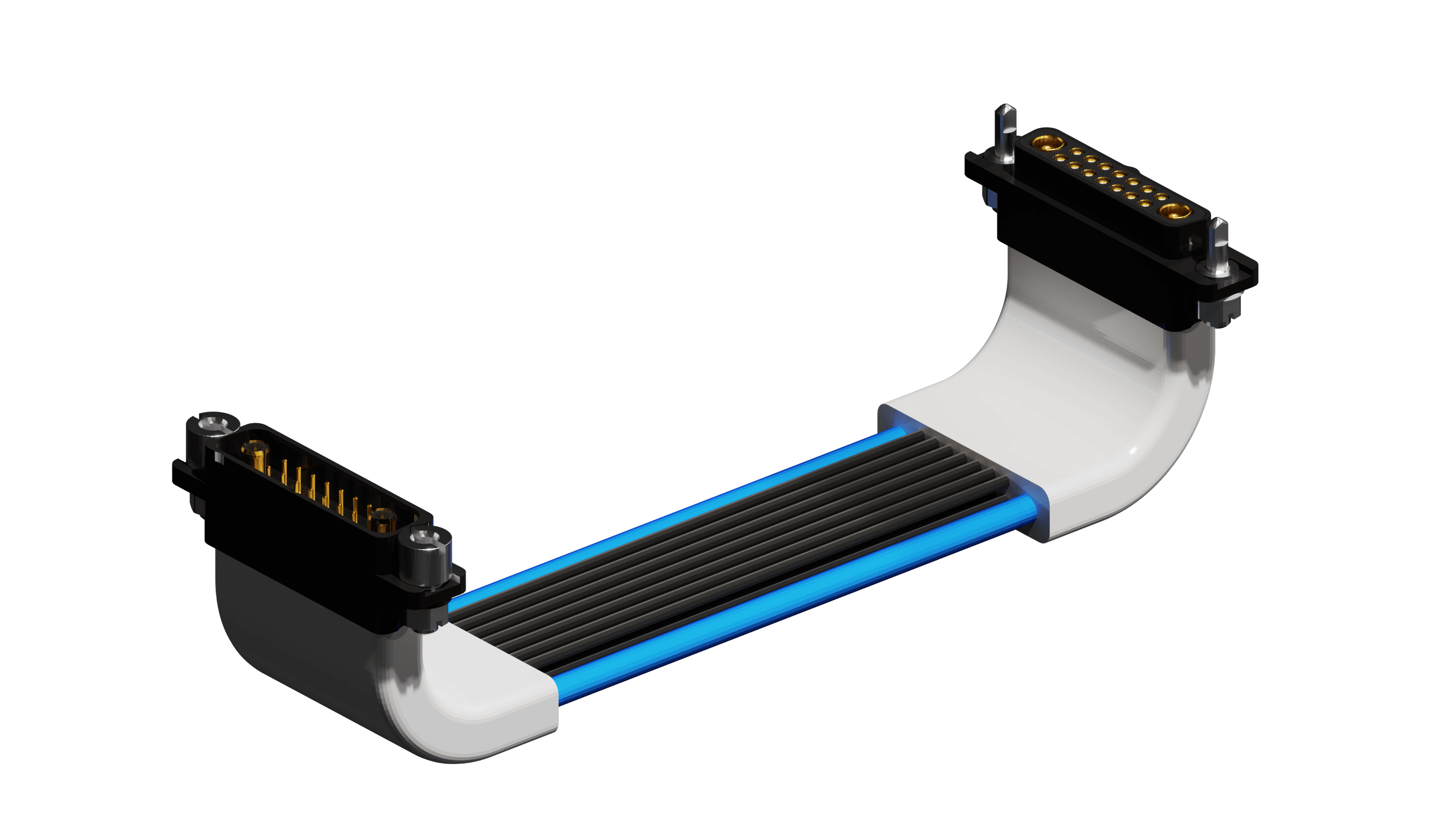

- Flexible FPC assemblies, enabling compact, aesthetic, and technical interconnections where flexibility is key.

Each component is designed to integrate seamlessly into your architectures, ensuring technical consistency, robustness, and easy maintenance.

💡Our role goes beyond simply delivering a connector or harness. We can also work directly on-site to prototype, assemble, or fine-tune a solution alongside your teams, reducing lead times and technical uncertainty.

Looking to secure your interconnections in harsh environments? Let’s discuss your technical requirements and explore together the best cable–connector combination for your application.