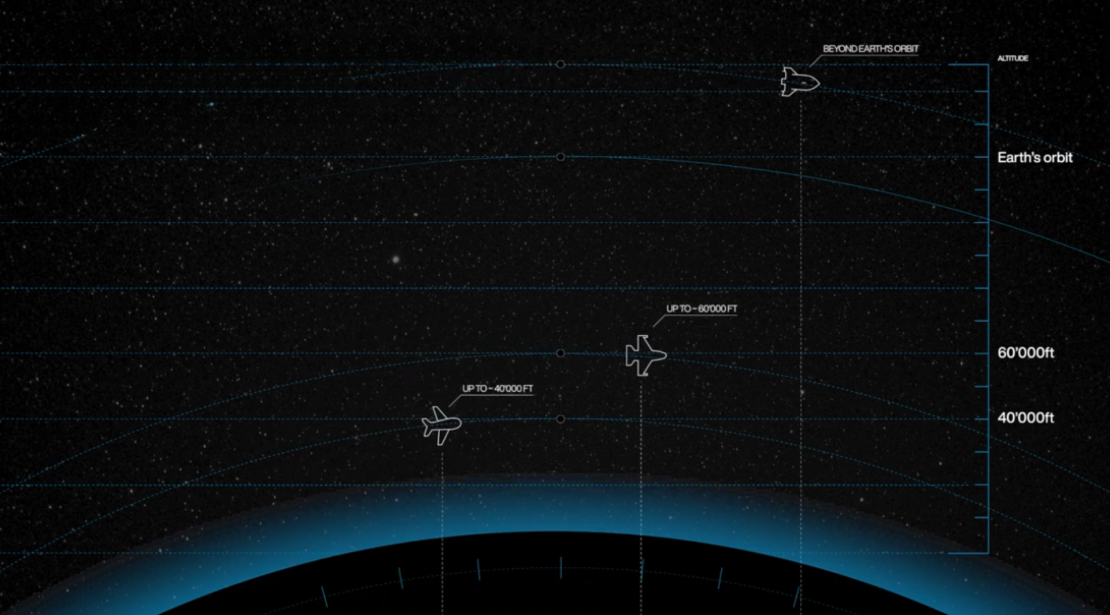

When an electrical system is used at altitude, whether in a commercial aircraft, a fighter jet, or a rocket, the performance of its connectors is directly affected.

As atmospheric pressure decreases, the dielectric strength of air is reduced.

The result: a voltage considered safe at sea level can cause a short circuit at 40,000 ft.

Why is this critical?

Incorrect voltage sizing as a function of altitude can lead to:

- in-flight failures,

- loss of electronic performance,

- costly redesigns and qualification delays.

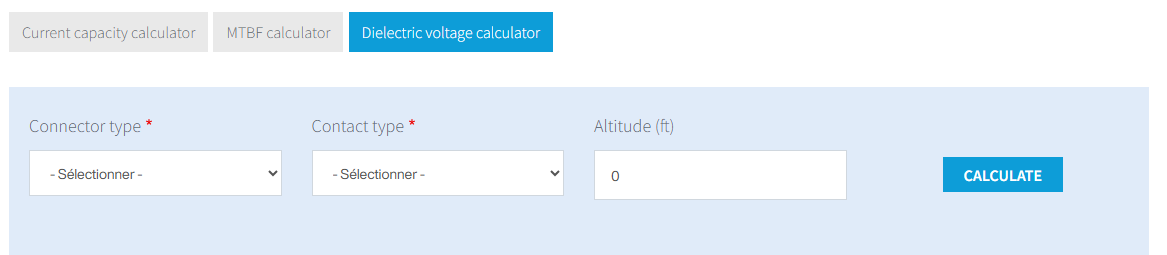

You can anticipate the connector behaviour in two steps: first, using our online Dielectric Voltage Calculator, and then with dedicated laboratory testing.

While the online tool provides a theoretical simulation of dielectric voltage at altitude, our laboratory tests validate performance under real operating conditions.

Simulate and Test Dielectric Voltage at Altitude

To support engineers, we developed a free online calculator.

It allows you to simulate the dielectric behavior of our connectors at different altitudes.

In just a few clicks, you can:

- Select a connector type (e.g., CMM)

- Define an altitude (e.g., 40,000 ft)

- Visualize the recommended voltage to prevent breakdown

👉Try our free online Dielectric Voltage Calculator now. Click here!

To go beyond simulation, Nicomatic’s laboratory also performs real dielectric voltage tests at altitude to validate connector behaviour under reduced pressure.

Thanks to the test equipment specially designed for this' breakdown voltage Altitude’ issue, short circuits can be prevented by adjusting the voltages used by the system.

We can perform tests according to your specific conditions of use and recommend the optimal voltage curve based on altitude.

Unlike standard testing facilities, our lab doesn’t stop at providing raw data, it delivers technical recommendations to help engineers interpret results and improve their designs.

Our agile approach allows close coordination with project timelines, ensuring tests are performed when needed without delaying production.

The laboratory’s expertise extends beyond Nicomatic products: it also conducts qualification and reliability tests for customers’ own components and systems.