Imagine your electronic system in flight, exposed to rapid temperature variations or operating at several thousand meters altitude. In these conditions, a discreet yet dangerous phenomenon can occur: air condensation inside the mating area of a connector. The result? Moisture settles between male and female contacts, drastically increasing the risk of a short circuit or creepage distance degradation.

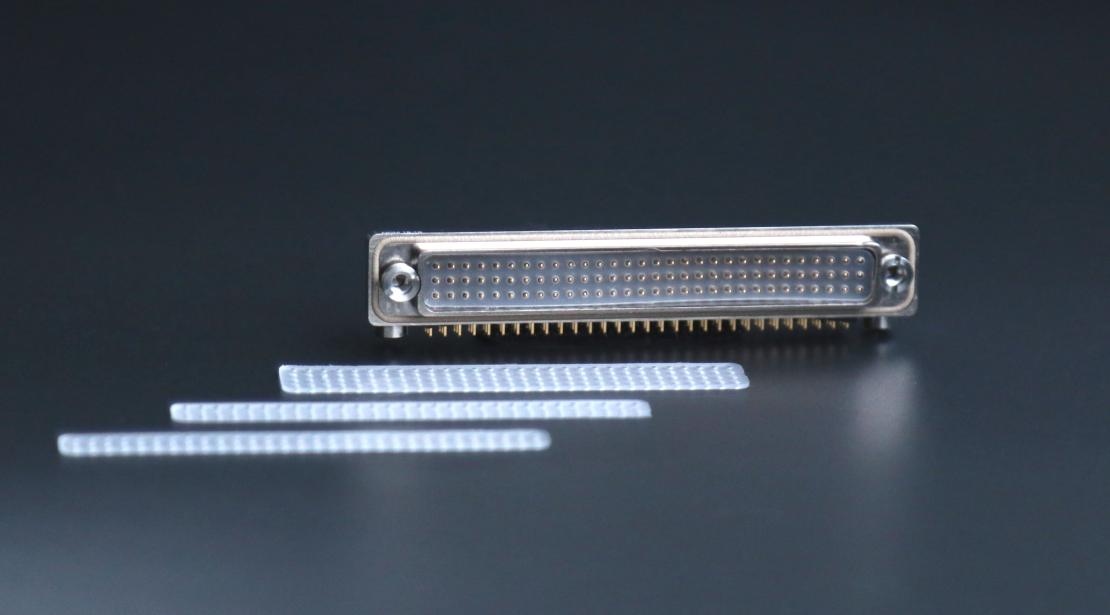

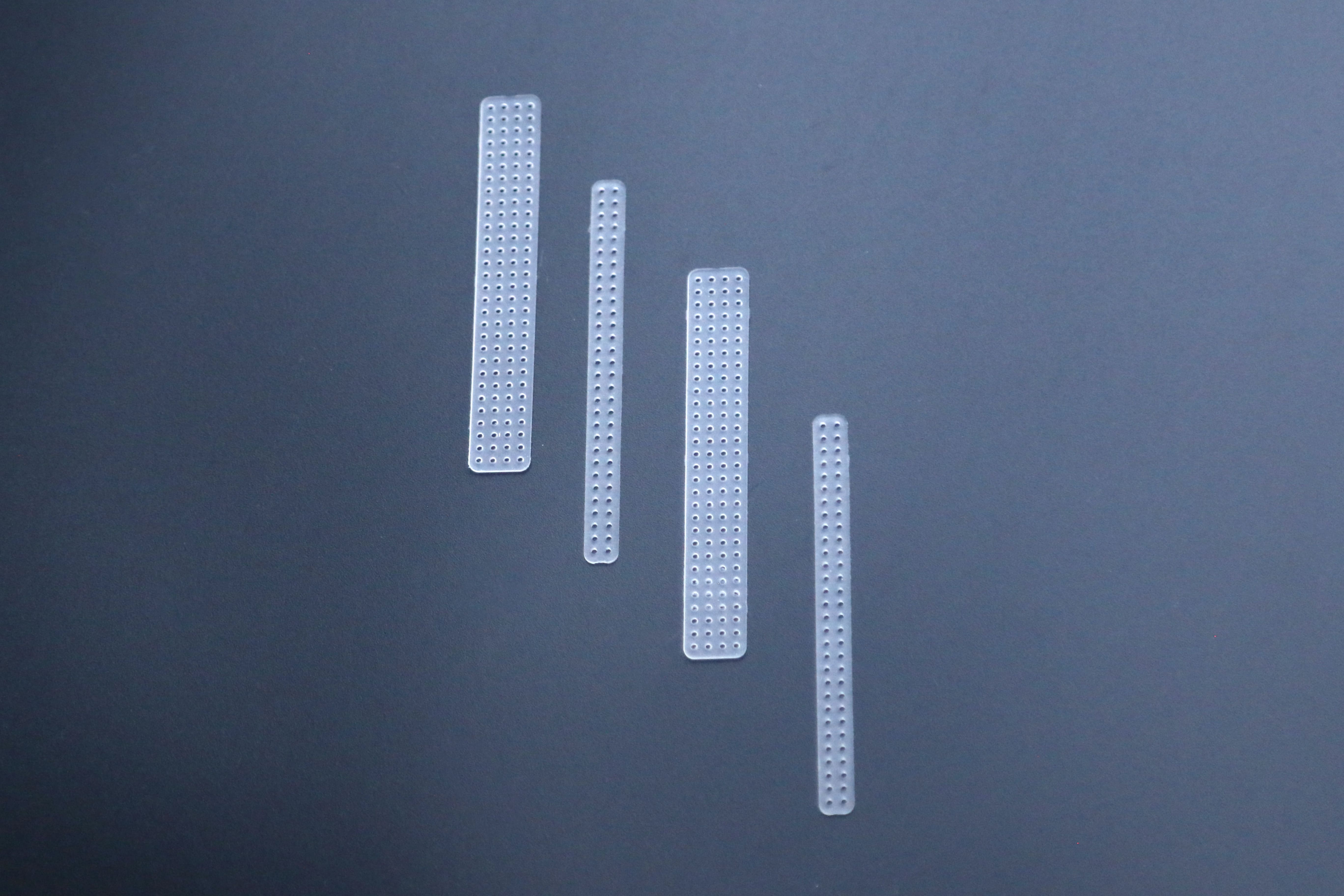

At Nicomatic, we offer a simple yet highly effective solution to secure your connections: the silicone interfacial gasket, available for our CMM and EMM series. Positioned between the two connector halves, this accessory acts as a protective barrier, strengthening system reliability even in the most severe environments.

Key Benefits of Interfacial Gaskets

1. Increased Creepage Distance

Silicone adds an extra insulating layer between contacts. This barrier reduces the risk of leakage currents, even in the presence of moisture, dust, or salt fog.

2. Reduced Risk of Electrical Arcing

By filling the micro-spaces between contacts, the interfacial gasket minimizes the chance of electrical arcs forming under high-voltage stress.

3. Maintained Insulation in Extreme Conditions

Thanks to its high dielectric strength, silicone retains its insulating properties even in the harshest conditions:

- Very high altitude

- Humid atmospheres

- Presence of contaminating fluids

Where a bare connector might see its performance compromised, the interfacial gasket keeps your connections secure over time.

Nicomatic interfacial gaskets are designed as an additional accessory for your CMM and EMM connectors. Easy to integrate, they enhance the reliability of your electronic systems in all critical applications whether in aerospace, space, or defense.

Working on a project exposed to severe conditions? Let’s talk. Our experts will guide you toward the best solution to ensure performance, safety, and long-term reliability.