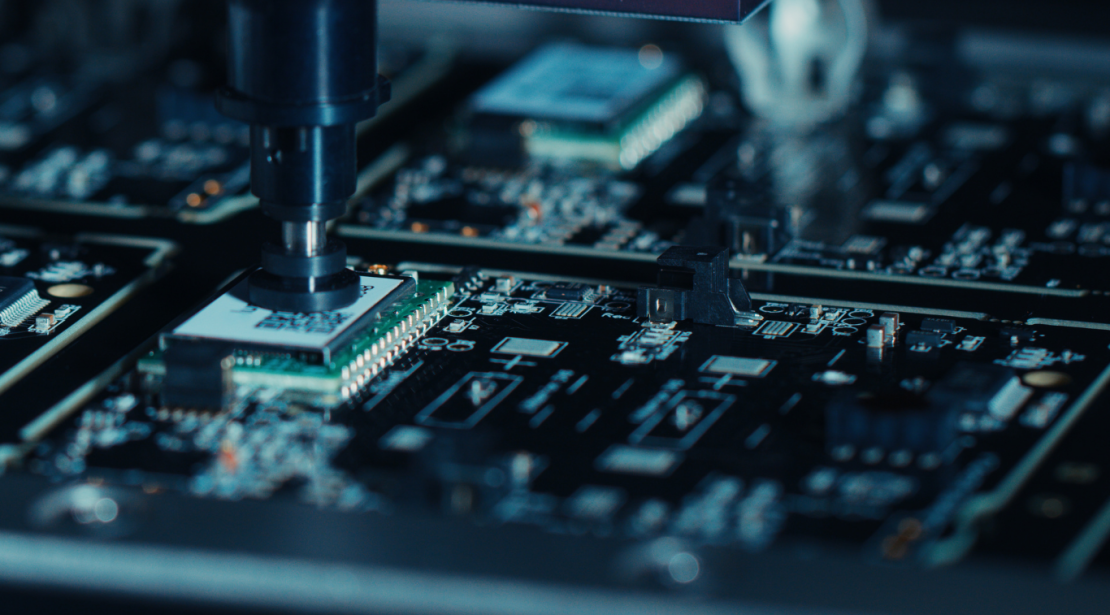

You may have faced this situation before: the board is ready to be designed, the components are selected, but one challenge remains. How can you find a connector that is both compatible with your pick & place lines and resistant to harsh environments?

In aerospace or defense, precision is non-negotiable. Engineers must balance process automation and mechanical robustness, while meeting the challenge of miniaturization.

It is precisely to meet this dual requirement that Nicomatic has developed the full SMT versions of its CMM (series 100 & 200) and EMM connectors: solutions designed to ensure reliability and direct integration into your automated production lines. Both contacts and mounting hardware are designed for seamless compatibility with automated processes.

With these solutions, you no longer have to choose between mechanical strength and automation. Your boards are ready for reliable, repeatable, and optimized assembly, directly on your production lines.

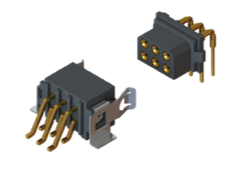

Soldered Mounting Hardware: Simplicity and Efficiency

This mounting hardware is soldered directly during reflow, without any manual intervention or tightening operation. It is particularly well suited to compact designs where mechanical constraints remain moderate.

Features: - Single soldering process for contacts and mounting hardware

|

|

Pin-in-Paste Mounting Hardware: Robustness and Repairability

This hybrid solution combines the advantages of through-hole and SMT automation.

Thanks to a mechanical reinforcement pin, it provides excellent tensile and shear strength, while remaining fully compatible with pick & place processes.

Features: - Compatible with automated SMT processes

|

|

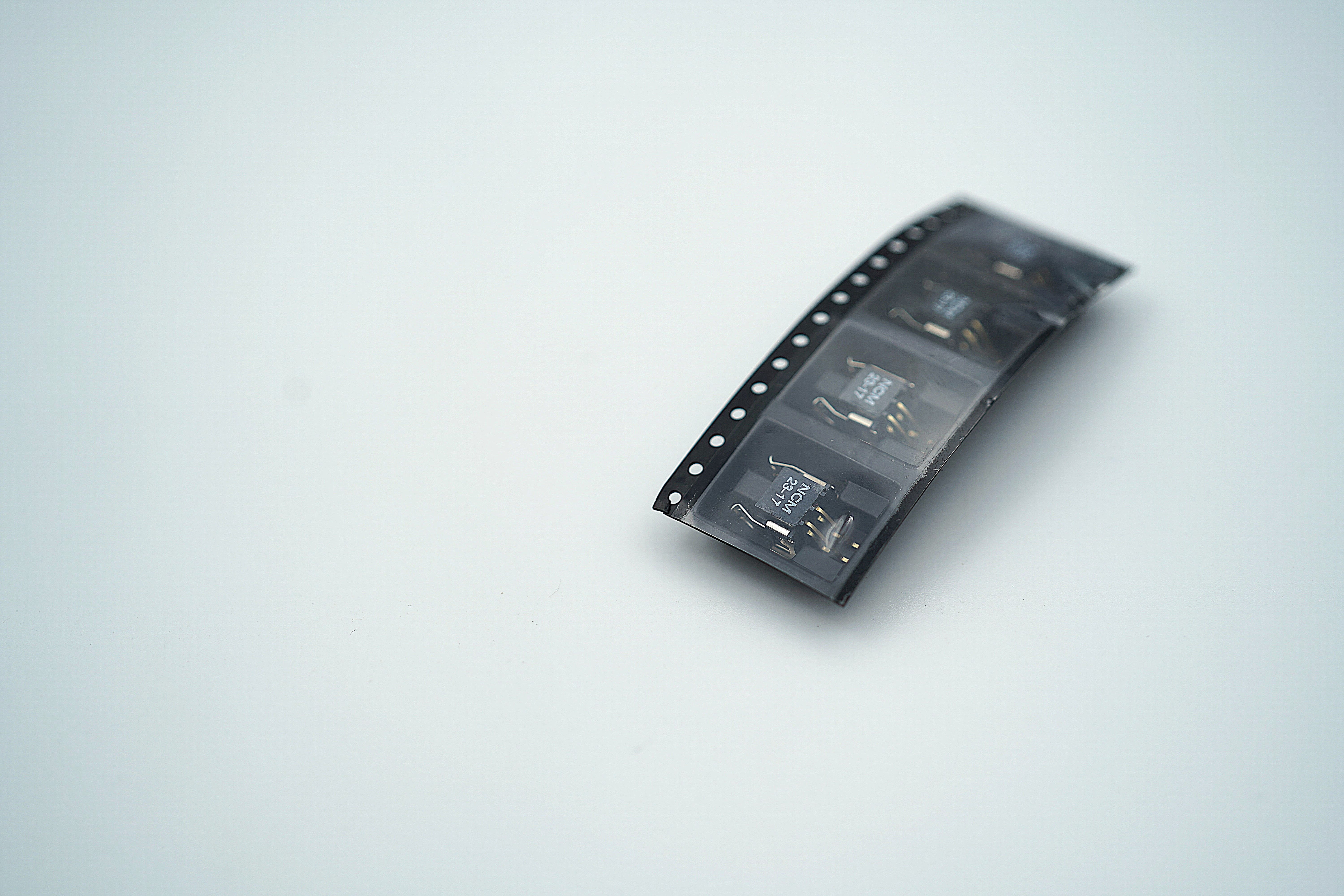

Packaging Designed for Automated Lines

Beyond contact and mounting hardware design, Nicomatic also offers packaging optimized for your pick & place equipment:

- Connectors supplied in tape & reel

- Packaging designed to reduce handling

- Shorter production cycle and improved repeatability

👉 Discover our dedicated article: Optimize Your SMT Assembly Process with Nicomatic Connectors in Tape & Reel Packaging

Easy Integration from the Design Stage

Because efficiency doesn’t stop at the production line, Nicomatic extends optimization all the way to the design stage.

Footprints allow you to integrate our connectors directly into your CAD tools, ensuring reliable results from the very start of your design. You can find those footprints on our online configurator.

All our SMT solutions comply with IPC-A-610 standards and are available with straight or right-angle contacts, meeting a wide variety of needs: board-to-board, board-to-wire, and high-density assemblies.

👉 To go further and secure your technical decisions, download our complete SMT guide: recommendations, checklists, and pitfalls to avoid.